Desiccant Cabinet Applications in Humidity Control

The number of opportunities for moisture related production faults can be reduced with the use of dry storage cabinets.

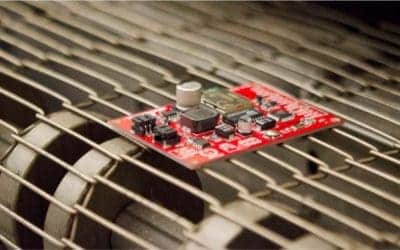

- Active Devices

Reduce moisture related damage to all types of active devices from PoP, Stacked Die, BGA, QFP, etc. - Passive Components and Connectors

Prevent solder defects by reducing the potential for oxidation of leads caused by excessive moisture during storage and kitting - Circuit Boards

Maintain accurate board dimensions with humidity controlled storage reducing board stretch and warp due to high moisture content - Ceramic and Blue Tape

Protect substrates and base materials from high moisture content - Silicon Wafers

Reduces contamination potential from particulates suspended in moisture droplets with a humidity controlled environment - Lead Frames & Carriers

Controlled humidity increases the reliability of solder and wire bond points with reduced potential for oxidation - Fiber Optics

Retards organic growth and maintains the condition of key fiber optics devices and components with a controlled environment. - Specialized Glass & Displays

Provides a controlled environment between process steps for switchable glass (LCG) components

For more information see: SMT Dry Boxes Website